CHY-TECH (HUBEI) TECHNOLOGY CO., LTD. is a wholly foreign-owned enterprise invested by CHY-TECH (H.K.) INDUSTRIAL CO., LIMITED in Jianshi County, Hubei Province. Founded in 2003, the company has invested over HKD 88 million in Hubei Jianshi to acquire land and establish the CHY-TECH Technology Park. The park spans more than 30 acres with a built-up area of approximately 20,000 square meters, housing an R&D center, office building, manufacturing workshops, an electronics laboratory, and a reliability testing center equipped with various instruments for physical, chemical, material, and hazardous substance analysis.

Guided by the core philosophy of "Technological Innovation, Customer First, Integrity in Operation, and Superior Quality," CHY-TECH is a high-tech enterprise specializing in new energy and intelligent system integration. Supported by a comprehensive R&D system and global quality certifications, the company has built a complete business ecosystem around "Integrated PV-Storage-Charging," offering a range of products and solutions including new energy charging and storage equipment, IoT terminals, software platforms, and system integration services.

In the new energy sector, CHY-TECH provides end-to-end services covering EV charging equipment, energy storage systems, charging station design and construction, O&M platform development, and supporting software. Beyond supplying high-performance hardware, the company focuses on delivering integrated new energy infrastructure solutions under the "Hardware + Platform + Operations" model. To date, CHY-TECH has forged strong partnerships with State Grid, CNPC, and local urban investment corporations, and serves as a charging equipment supplier for leading automakers such as BYD and BAIC, steadily expanding its footprint in the new energy market.

In the domain of Intelligent IoT, the company engages in IoT system integration and terminal equipment R&D, contributing to key projects in Smart City, Smart Forestry, Smart Water Conservancy, and Smart Education. Its self-developed IoT terminals and system platforms have been successfully implemented in critical scenarios including urban safety, flood warning, and slope monitoring. Through collaborations with universities and research institutes, CHY-TECH promotes the application of IoT technologies in public safety and urban governance.

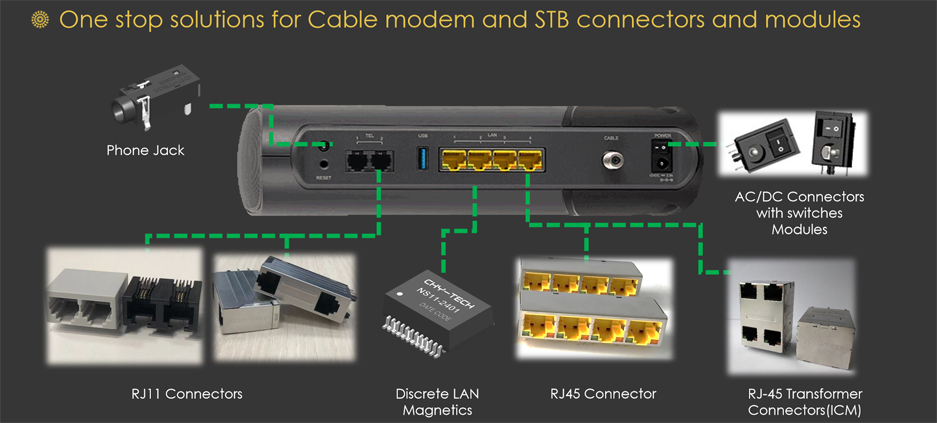

In the 3C electronics segment, as a key supplier to the global broadband communication market, the company provides power supply and network connectivity components to industry leaders such as Cisco, Technicolor, and CommScope. These products are mainly exported overseas via top-tier electronics manufacturing services (EMS) providers including Foxconn, Flex, and Pegatron.

CHY-TECH places strong emphasis on technological innovation and intellectual property, holding more than 40 patents and a portfolio of software copyrights. The company has established an efficient system for commercializing R&D outcomes: multiple hardware-related patents have been translated into market-ready products achieving mass production, while its self-developed software platforms—including the "Slope Monitoring Management System," "Integrated PV-Storage-Charging Operations Platform," and "Smart Parking Management System"—have obtained national software copyright certificates and are being deployed in key projects across smart city and green energy sectors, creating synergistic "hardware-software-system" capabilities. Ongoing development and validation of new critical electronic components and system modules continue to fuel the company's innovation and industrial growth.

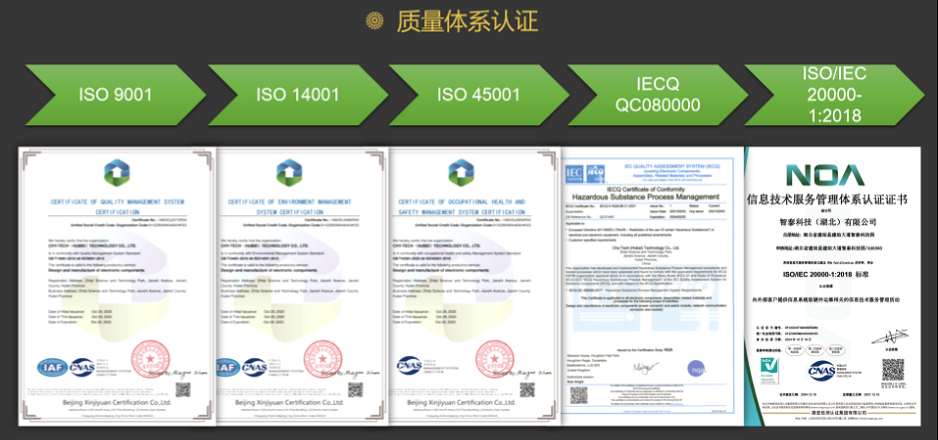

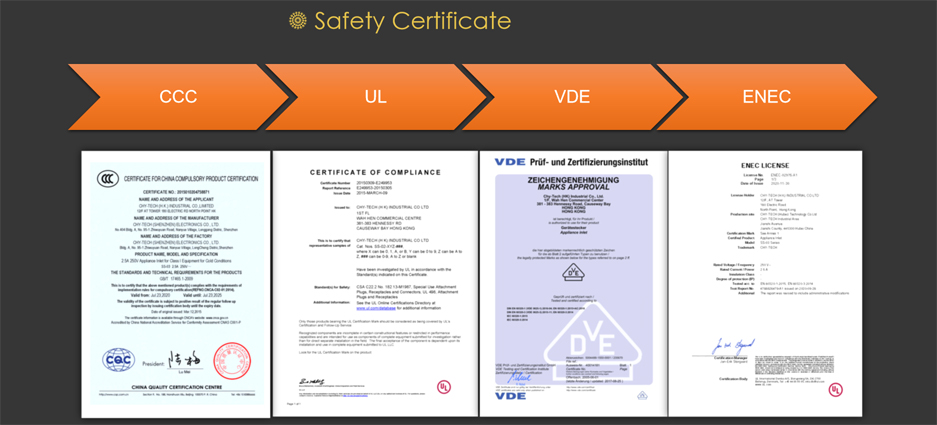

The company has obtained multiple international management system certifications, including Quality Management (ISO 9001:2015), Environmental Management (ISO 14001:2015), Occupational Health and Safety Management (ISO 45001:2018), Hazardous Substance Process Management (IECQ QC 080000:2017), and IT Service Management (ISO/IEC 20000-1:2018). These certifications underpin an internationally aligned operational and service management framework, supporting the company's strategic vision of "Sustainable Development and Long-term Operation."